Rotomolding companies: what they do and whichindustries they serve

25 de October de 2024 - Rotomolding

In the industrial world, companies are racing to deliver high-quality, durable, and versatile products. In this scenario, rotomolding companies have a competitive edge.

With innovative processes, these companies can serve different market segments by offering fully customized solutions that meet the specific needs of each sector with excellence.

But what exactly is rotomolding? Here, we’ll explore the evolution of one of today’s most promising markets. You’ll also learn about the unique advantages of this process and where its results are applied. Enjoy the reading!

What is rotomolding?

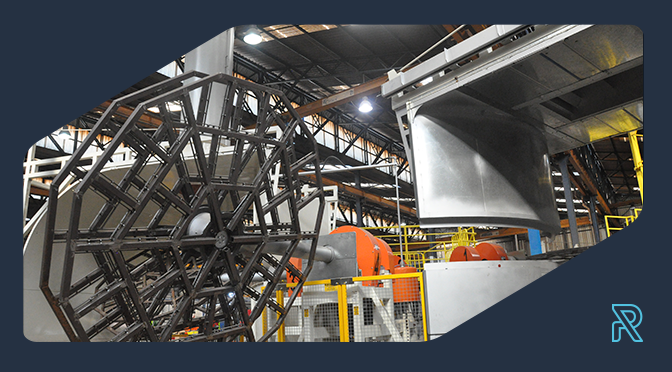

It is a manufacturing process used to create hollow plastic parts. Another name for this technique is rotational molding. Shapes and sizes vary according to the mold’s specifications. In practice, the process involves heating a mold containing polymer material while it slowly rotates on two axes. This allows the plastic to melt and spread evenly inside the mold, resulting in a smooth, seamless final product.

This method is widely used for its ability to produce large items economically and with guaranteed durability. We explain in detail how rotomolded parts are developed in another article on our blog: Check it out!

The evolution of rotomolding companies

With technological advances and the growing demand for customized solutions, rotomolding companies have continued to improve in terms of innovation and production capacity.

Originally, the rotomolding process was mainly used to create simple household products such as trash bins, trays, coolers, fuel tanks, and playground equipment.

We specialize in more technical and demanding sectors

We manufacture a variety of custom parts for the agricultural and industrial sectors, delivering large volumes of items with high mechanical strength and chemical resistance:

- Agricultural Tanks

Used for storing and transporting liquids on farms, agricultural tanks produced through rotomolding are extremely durable and resistant.

● Technical Parts

Many industries require specific plastic components for their machinery and equipment. Custom-made solutions effectively meet these demands.

Which industries are served by rotomolding companies?

The versatility of rotational molding is proven by the wide range of sectors that use these plastic parts, which are not only durable but also sustainable:

● Agribusiness

We highlight components for agricultural machinery, such as seed and fertilizer hoppers for planters, sprayer tanks, and hydraulic oil tanks for self-propelled equipment. These solutions ensure efficiency and productivity in the field.

- Industry

Rotomolding also meets the demand for customized components across various industrial sectors, especially those requiring resistance to extreme conditions, such as high temperatures or chemical exposure.

- Civil Construction

In a field where material strength and durability are essential, rotomolded products, such as water tanks, pipes, and reservoirs, are widely used in civil construction.

The benefits of rotomolding

When compared to other plastic manufacturing processes, this method offers unique advantages:

- Durability, especially in challenging environments like rural settings;

- Excellent cost- effectiveness, particularly for large-scale production;

- Design flexibility, enabling the creation of custom models.

Looking for the best solutions for your business?

Visit our website! There, you’ll find our full product range, including images, technical specifications, and usage recommendations. If you have any questions, our team is also available on WhatsApp.