What is it?

Explaining rotomolding

A guarantee of a long-lasting solution

Material

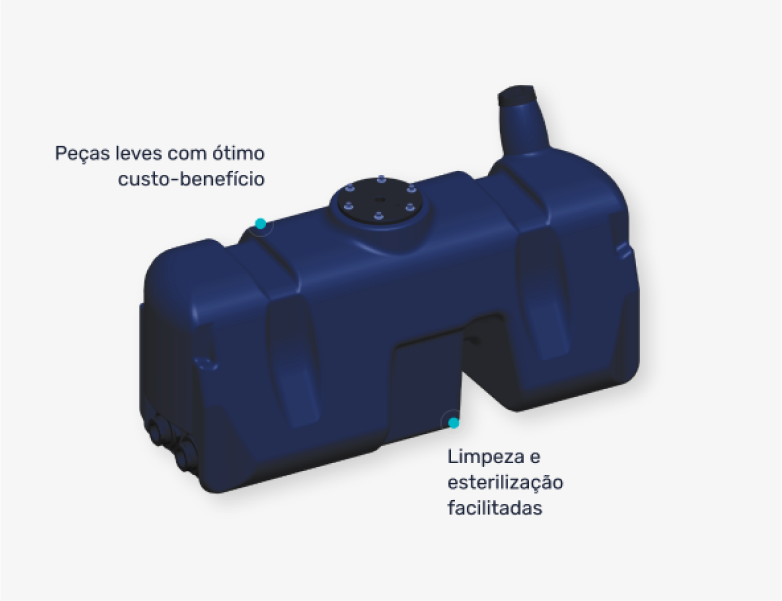

The rotomolding process involves transforming plastic polymers into hollow parts, allowing the production of lightweight components with excellent cost-effectiveness. Polyethylene is used as apowdered raw material. The parts are unique and seamless, making them easier to sterilize and clean.

We are experience

Rotoplastyc has been using this process for over 25 years, investing intechnology and continuous improvement to serve different industry sectors.

We want to be part of your company’s DNA, which is why we value innovative and standardized processes.

Your results are ours.

Skilled professionals with extensive technical knowledge, transparency, and a results-driven mindset work alongside you to develop your project.

Our industrial sales and engineering teams assess each company’s needs to deliver a product that meets the demands of both the industry and its customers.

Learn about Rotoplastyc

Beyond your expectations

All our processes and teams pursue the same goal and follow our Quality Policy, ensuring the delivery of parts that fully meet our clients’ expectations.

Develop your project

Quality Policy

Positively surprise our clients and partners with our technical and human competence.

Satisfy customers with quality services through continuous improvement, team training, and process standardization.

Solutions

Complete infrastructure

Complete infrastructure with

engineering, modeling, die-

making, and content

laboratory.

Projects designed for your industry

We can develop pieces of different shapes and sizes, creating a personalized shopping experience for your industry.

Request a quote